High efficiency evaporation at lab-scale

AGI Thin Film Evaporator (also known as Wiped Film Evaporator) is ideal for separating volatile components from heat sensitive, viscous and fouling chemical mixtures. Thin film, under low pressure, reduces the boiling point of chemical components, as well as the hydrostatic pressure, resulting in the evaporation of volatile fraction at low temperatures. The PTFE wipers form a thin film on the evaporation column and push the film downwards with every rotation. This causes the heat-sensitive components to experience short residence time on the evaporation area and minimal thermal degradation.

The all-glass design of our Thin Film Evaporator allows for continuous visual monitoring, and the adjustable feed rate provides control over film formation.

- Short residence time

- Minimal thermal degradation

- Low pressure of up to 0.1 mbar (abs.)

Why should you choose a glass thin film evaporator?

A glass evaporator is ideal for process development and troubleshooting applications. An all-glass design ensures high visibility of the process, as opposed to steel evaporators. This means that any undesired events that might occur during process development can be easily observed and rectified.

AGI Thin Film Evaporator offers excellent performance at lab scale. Separate a variety of volatile mixtures at low temperatures and low thermal degradation. Our Thin Film Evaporator is suitable for small-scale processes, process development, pilot and troubleshooting studies.

- Bulk removal of volatiles from heat sensitive mixtures

- Shorter residence time compared to other evaporation systems

- Uniform thin film formation by PTFE wipers

- Reliable Temperature control

- Process visibility due to all glass design

- High degree of vacuum due to magnetic sealing

- Greaseless joints for contamination free processing

- Operating range up to 200 °C, 300 °C as option

- Stand with castors for mobility

Customization possibilities

AGI Thin Film Evaporator can be customized and we are happy to discuss the design of custom features with you in order to meet your specific process requirements. Many applications benefit from adjusting the material properties and/or physical size of the evaporator.

Features

Wiper system

- Short residence time on the evaporation surface

- Gentle distillation at low temperature

- Less damage to the heat sensitive chemical fraction

- Low fouling on the evaporation surface

Evaporation performance

Different components evaporate at different rates in both thin film and short path evaporators. We studied the evaporation rates of different solvent types, which you can see in the graph on the right.

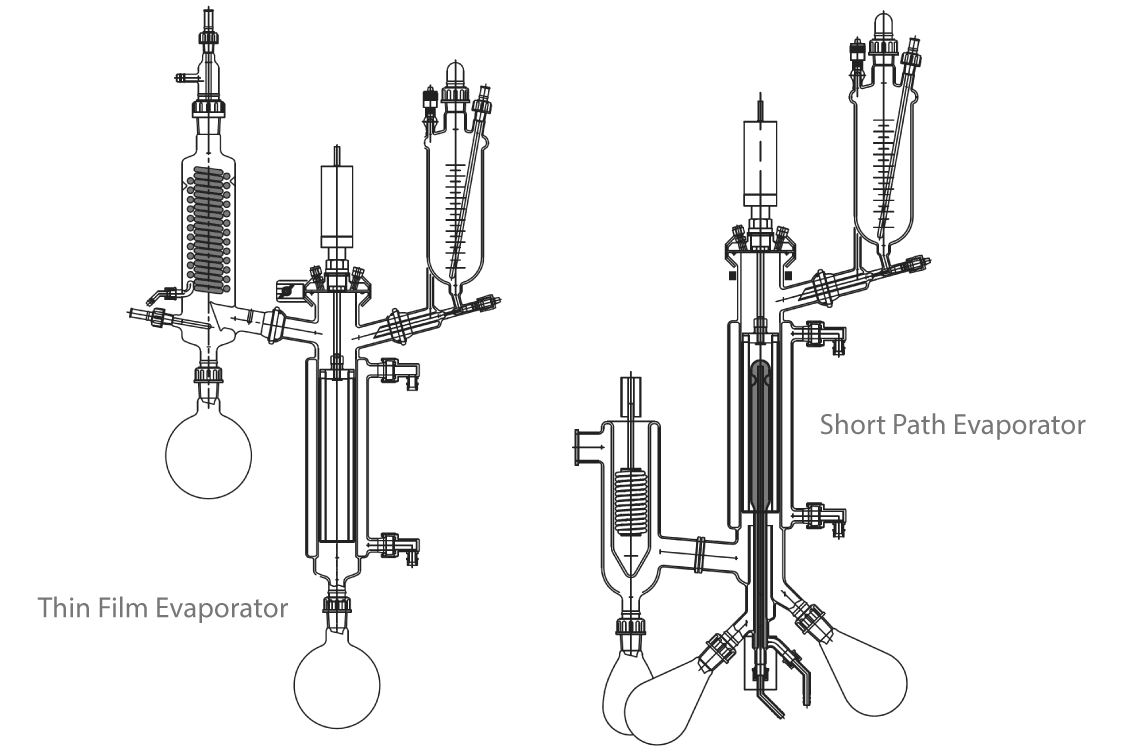

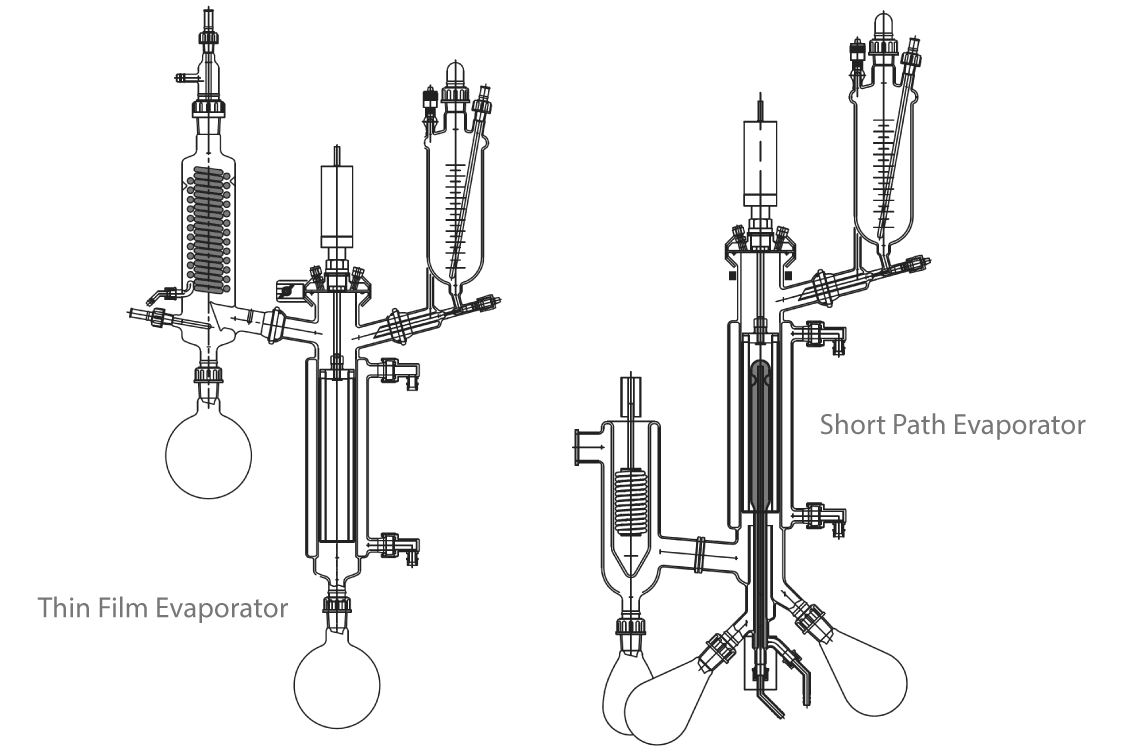

Difference between Thin Film and Short Path Evaporator

The main differences between AGI Thin Film and Short Path Evaporator are the operating pressure and the position of the condenser.

| |

Thin Film

Evaporator |

Short Path

Evaporator |

| Design Pressure |

0.1 mbar (abs.) |

0.001 mbar (abs.) |

| Condenser |

External condenser |

Internal condenser |

Easy installation and dismantling

AGI Thin Film Evaporator can be easily installed without the use of complex tools or steps. The rotary wiper can be easily removed for cleaning and reinstalled.

- Easy to clean and maintain

- Prevents cross-contamination from batch-to-batch

Specifications

| Evapration surface area |

0.05 m² (DN 60)

0.1 m² (DN 100)

OPTION: +300 °C in jacket with PBI* wiper

|

| Operating pressure |

0.1 mbar (abs.) to atm |

| Maximum temperature |

+200 °C in jacket with PTFE wiper |

| Operating jacket pressure |

Up to +0.5 barG (+0.05 MPa) |

| Feed rate |

0.1 to 1.5 kg/h (DN 60)

0.3 to 3.0 kg/h (DN 100)

|

| Maximum wiper rotation speed |

DN60 300rpm (continuous) 350rpm (Intermittent) |

| Maximum viscosity |

Up to 1,000 mPa.s (custom-made)

DN100 200 rpm (continuous), 250rpm (Intermittent)

|

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM