Elegant, cost-effective, small, and incredibly capable, the EcoClean offers the capability of leading-edge front-end semiconductor systems at a fraction of the size and cost of competitors. Create advanced solutions for current and next-generation technologies with this perfect “sweet-spot” system for the emerging “More than Moore” processing requirements of MEMS, Power, LED, Micro LED, RF, sensors, and biotech.

High-Density Plasma

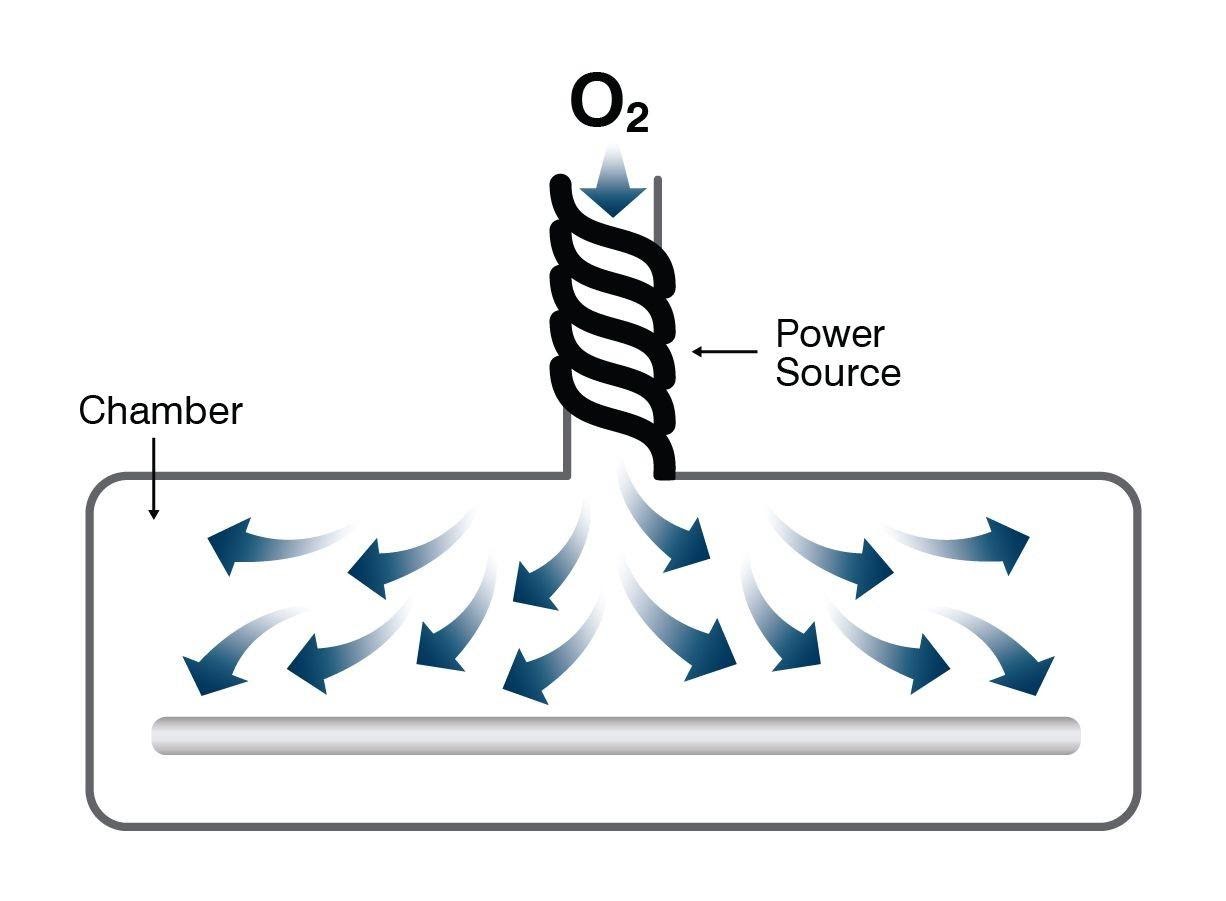

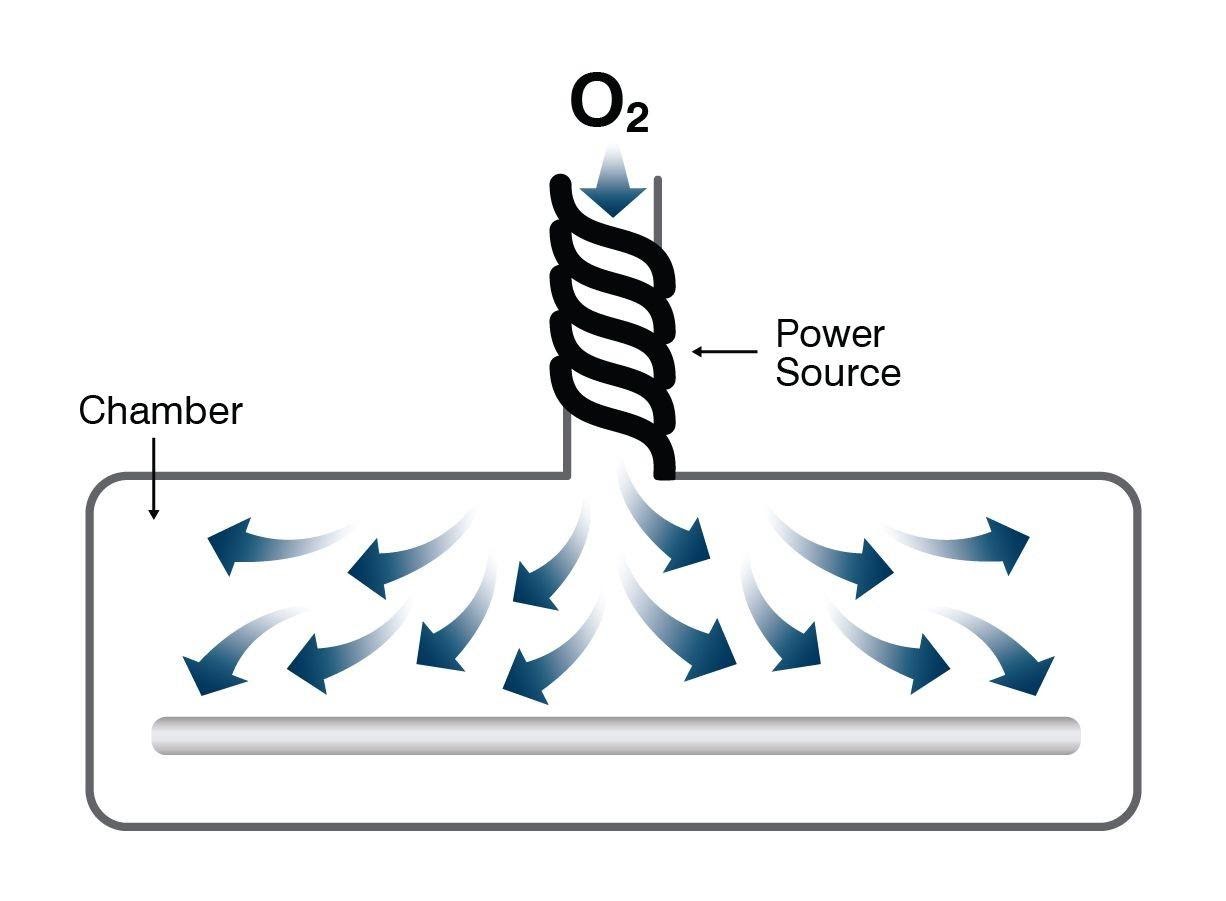

YES EcoClean systems use oxygen and nitrogen atoms created in high-density plasma for cleaning/stripping rather than the gallons of toxic chemicals and water required by wet cleaning systems. By using a downstream resist strip process, EcoClean systems achieve a high removal rate with no electrical damage or defects to substrates.

Our remote source produces a high-density plasma with the advantage of confining charged plasma species within the plasma chamber, ensuring that only charge-neutral species flow from the source and interact with the substrate. The end results are much higher throughput with low gas utilization, lower capital costs, and a safer, greener automated process.

FEATURES

- Downstream plasma and distributor

- Small footprint with single chamber (<0.75 m²)

- Highly reactive neutral species

- Elegant system with only 3 moving parts

- Controlled O, H and F species

- State of the art parts – readily accessible

- R&D to high-volume production with minimal downtime

- Flexible wafer size: 2” to 8”

- Low gas usage

BENEFITS

- High strip/descum rate – 100-100,000 Å/min (0.01 – 10 um/min)

- High throughput – up to 65 wph process

- 2x lower CoO and ½ the footprint

- No defects or damage due to ICP downstream plasma

- High reliability with >95% uptime

- Eco-friendly “green” process

APPLICATIONS

- Photoresist removal

- PR descum

- Polyimide removal

- Organics removal

- Copper oxide removal

SECTORS

- Advanced Packaging

- MEMS

- Compound Semiconductor (LED, uLED)

- Power Devices

- Sensors

- Biotech and Bio-sensors devices

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM