Ideal system for pilot scale crystallisation and filtration

AGI Pilot Plant Filter Reactor PLUS is designed to fulfill demanding crystallisation processes. Integrating the functionality of a reactor and a filter in one system, a full crystallisation process can be performed in the reactor without ever opening the vessel. Processes range from crystal formation, filtration, product washing and drying.

Large quantities of crystalline product can be processed easily and safely in the Pilot Plant Filter Reactor PLUS, making it ideal for process development, kilo lab and pilot scale production.

- Reaction, filtration and washing in one vessel

- Contamination-free material processing

- Vessel swing/rotating mechanism for easy product collection

AGI Pilot Plant Filter reactor PLUS is designed to accommodate reaction and filtration processes in one vessel. Most types of crystallisation process can be performed in this system with a simplified work flow.

- Reaction and Filtration in a single vessel

- Easy access to filter using a lever mechanism

- Design that safeguards against product loss

- Easy cleaning and maintenance

- Scale-up up to 100 L

- Space, time and cost saving

- Wide process temperature range: -90 °C to +200 °C

- Support structure with castors for mobility

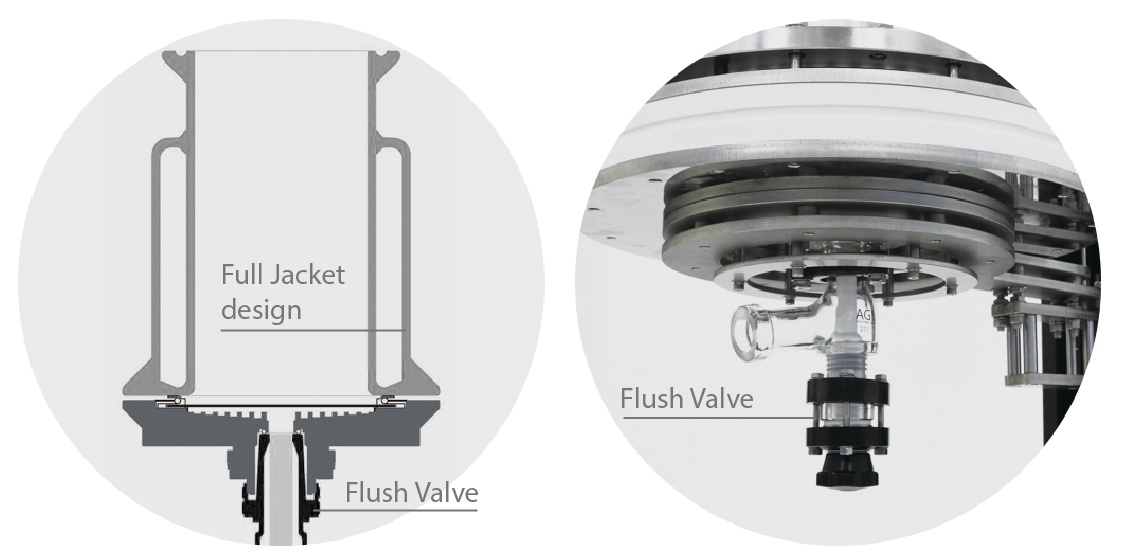

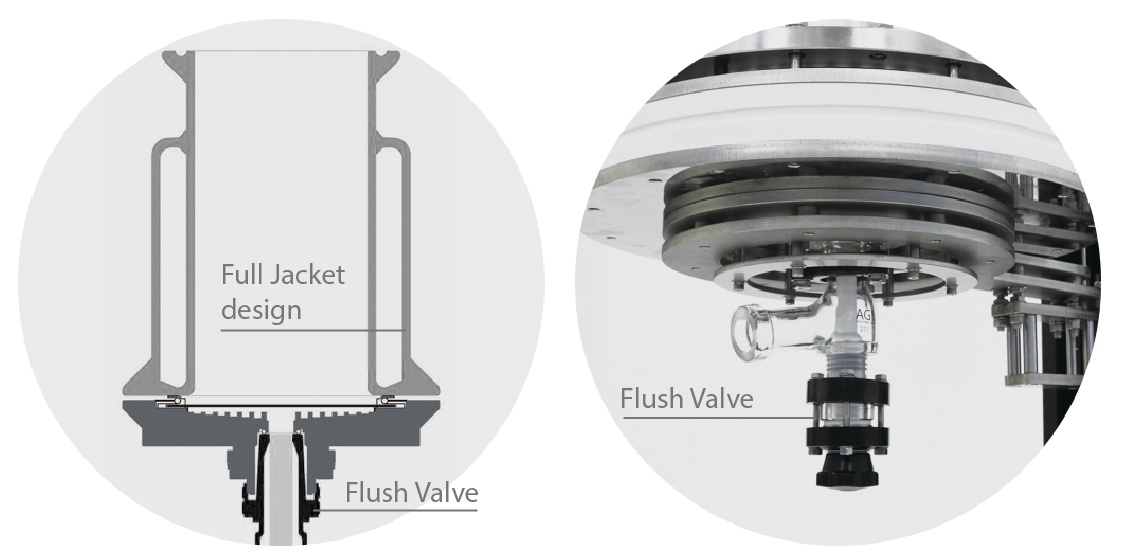

- Vessel with full jacket design for maximised thermal transfer efficiency

Features

Recover end product with absolute ease

The filter can be quickly uncoupled, lowered, and moved sideways for filtrate collection.

Effective filtration

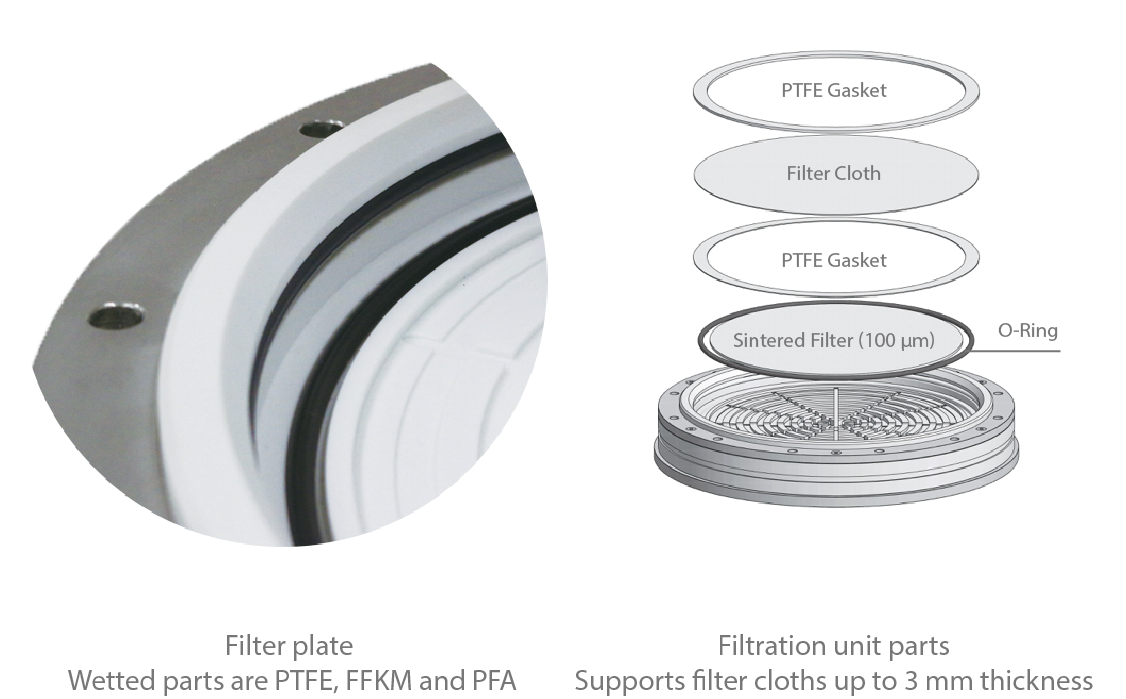

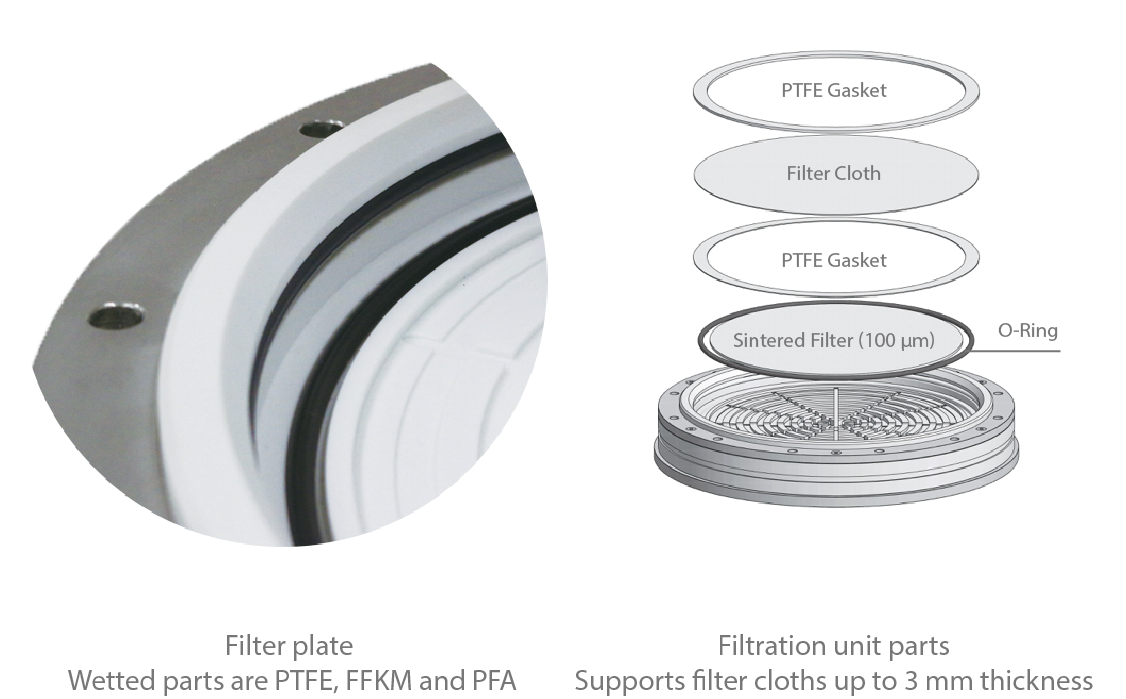

The sintered filter (pore size of about 100 μm) supports the filter membrane. Double PTFE gaskets that sandwich the filter cloth lock everything into place. This setup, along with an O-ring, prevents leaks (including solids, liquids, and gases), and bypasses when the filter is closed. Filter membranes of up to 3 mm thickness can be used.

Full jacket design for high thermal performance

- High performing vessel

- Filter with low dead volume

Optimize your process with accessories

AGI Pilot Plant Filter Reactor PLUS is best suited for kilo lab/pilot plant production and process development applications. The PFA-coated SS Lid has adaptable multipurpose 40 A ports with accessories such as purge port, pressure gauge, hand hole, safety valve, condenser, dropping funnel, condensate cooler, condensate receiver, stirrer seal, and temperature sensor. These accessories help to fine tune your crystallisation and create an optimal process.

Clean with ease

Unlike the flanges with grooves, flat flanges are very easy to clean and maintain.

Stable and debris-free stirring

Newly designed AGI stirrer bearings have an extended configuration with glass and PEEK sliding parts. For pilot plant reactors, taper type stirrer bearings are used.

Impeller options

AGI impellers are made of SS rods encapsulated in PTFE for excellent chemical resistance and mechanical strength.

Specifications

| Vessel capacity |

10 L, 20 L and 30 L |

| Vessel type |

Double wall, full jacket |

| Filtration area |

317.3 cm² (10 L), 514.7 cm² (20 L), 711.6 cm² (30 L) |

| Operating pressure |

Full vacuum to atmospheric pressure |

| Operating jacket pressure |

Up to +0.5 barG (0.05 MPa) |

| Operating temperature |

-90 °C to +200 °C |

| ΔT - Thermal shock resistance |

110 °C (double wall) |

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM