Overview

You do not have to be present to open the chamber door slightly before initiating the drying cycle because an optional air pump is used to push hot moist air out of the chamber. The internal heater and optional pump make drying in the HRM-242? rapid and efficient.

| [ Model / Effective capacity ] |

|

| HRM-24II |

Features & Functions

- Temperature and time can be set with easy operation.

- Selectable drying time

- Memory function

- Optimal drying is always possible.

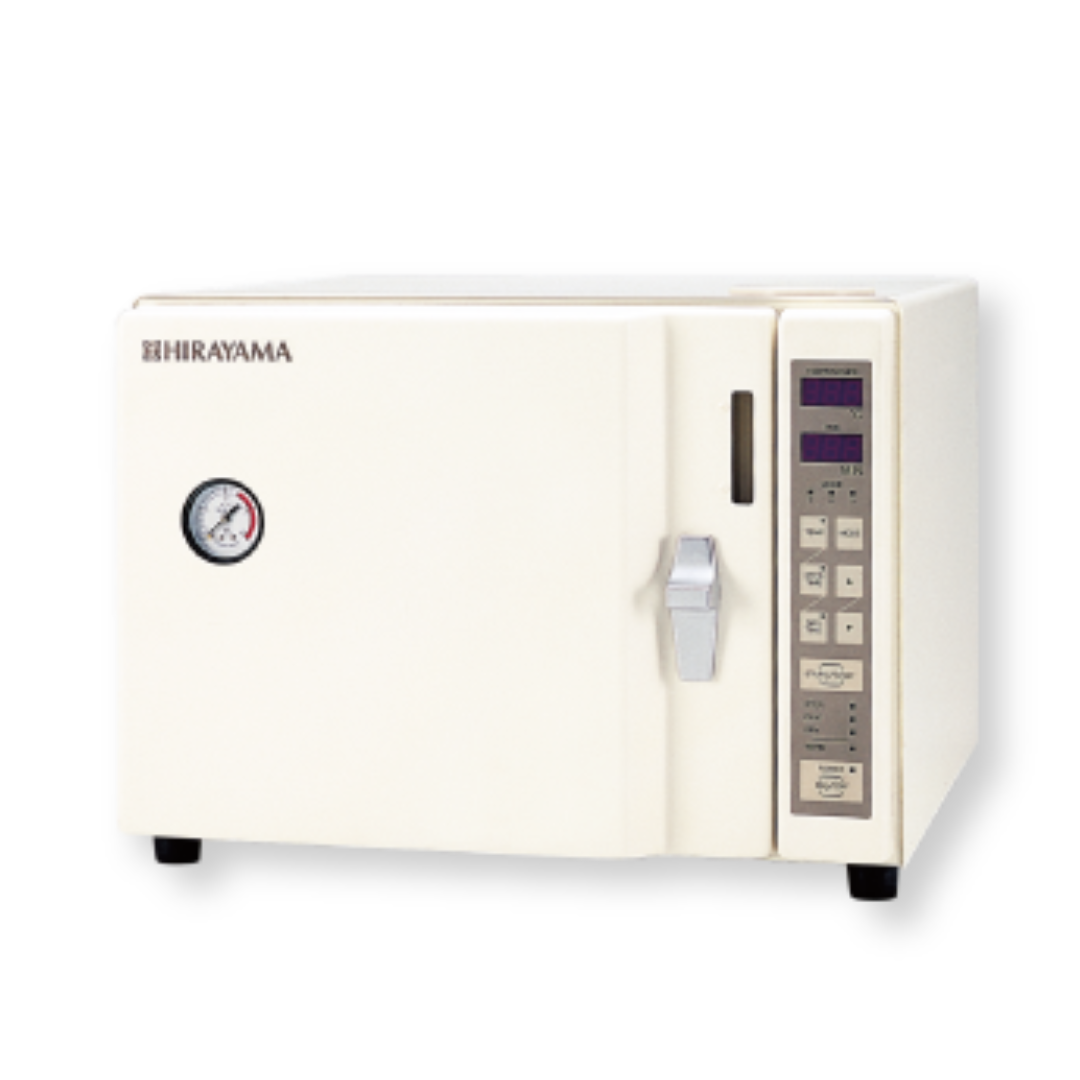

One-touch door interlock mechanism

The sliding door latch system offers convenient, one-touch door opening and secure closing. For safety, the door cannot be opened while the chamber is pressurized.

Automatic one-touch program selection

Depending on the load to be sterilized, you can access from three preset programs at the touch of the MODE button:

1) Sterilization-Exhaust-Drying

2) Sterilization-Rapid exhaust (solids)

3) Sterilization-Exhaust (liquid)

After selecting the desired program, merely pressing the START key will automatically initiate and complete the program from sterilization through drying (if selected). The default parameters in each program can be changed quickly from the keypad. Once changed, the new values are retained in memory until reprogrammed. Thus, the same cycle can be repeated merely by pressing the START key.

Automatic steam exhaust system

In the liquid cycle, the automatic exhaust system is activated after completion of sterilization, providing controlled, unattended rapid cooling down, but without the risk of boiling over. In the solid goods cycles, steam is exhaust more rapidly after sterilizati-on.

Full sterilization with efficient drying

The microprocessor executes the sterilization cycle with accurate and precise temperature control. An internal drying heater is used to dry the load more efficiently than an external heater.

Fully automatic drying system (option)

Unlike other bench-top sterilizers, the HRM-242II is truly automatic from start of sterilization to completion of drying. You do not have to be present to open the chamber door slightly before initiating the drying cycle because a air pump is used to push hot moist air out of the chamber. The internal heater and pump make drying in the HRM-242II rapidly and efficiently. Note: The air pump is an option which can be installed in the field.

Compact design plus easy maintenance

The unit requires only 505W x 535D mm of bench top space. A see-through tubing indicates the water level in the water reservoir so that it is easy to know when more water is needed in the reservoir. Draining and cleaning of the reservoir in routine maintenance is easy: just lower the water level tubing to a horizontal position and collect the outflow in a container.

Safety features

The array of safety features include a pressure relief valve, over-pressure power cutoff, low-water power cutoff, and circuit breaker. In addition, warning lamps and audible alarms alerts you to any abnormal condition or malfunctional components. An on-board self-diagnostic system for troubleshooting rapidly pinpoints malfunctioning components, thereby minimizing downtime and service costs.

Operation Cycle

| Sterilization - Drying |

|

Heating |

|

Sterilization |

|

Exhaust, Drainage |

|

Drying |

Main applications: Sterilization of gauzes, fabrics ( Material which requires drying after sterilization), Additional drying of gauzes , fabrics

|

| Sterilization |

|

Heating |

|

Sterilization |

|

Exhaust

(Rapid) |

| Main applications: Solids |

| Sterilization |

|

Heating |

|

Sterilization |

|

Exhaust, Drainage |

| Main applications: Liquid |

Option

Round dressing drum

stainless steel |

Rectangular sterilization container

stainless steel |

|

|

| φ170 x H120 mm |

W310 x D130 x H80 mm |

Specifications

| Product name |

HRM series Bench-top Autoclaves |

| Model |

HRM-242II |

| Effective capacity |

16 L |

| Chamber size (φ x H mm) |

240 x 360 |

| Operation mode |

Sterilization - drying, Sterilization (For Solids / For Liquid ) |

| Sterilization temperature setting range |

105°C - 134°C (in 1°C increments) |

Time setting

range |

Sterilization |

1 min - 60 min, variable |

| Drying |

1 min - 90 min, variable |

| Drying method |

Internal drying heatetr

(optional) Air pump for fully automatic drying system |

| Water supply / drainage method |

Water tank (circualtion type) |

| Safety devices |

Over-pressure relief valve, Over-pressure power cutoff with alarm, Low water power cut off with alarm,

Microprocessor malfunction detection device with alarm, Circuit breaker |

| Outside dimensions (W x D x H mm) |

505 x 535 x 380 |

| Net weight (Approximately) |

39 kg |

| Pressure vessel category |

Simple pressure vessel |

| Power supply |

AC120V / 220V / 240V, 50Hz / 60Hz Single-phase |

| Required power supply facility |

1.2kW |

| Power connection |

Ring terminal |

| Supplied accessories |

Bottom plate, Drainage filter, Fuse |

?Specifications and appearance are subject to change without notice due to continuous product improvement.

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM