In the past decade, with the optimization of tungsten filaments and electronic circuits, especially the use of compound filaments, the resolution of filament electron microscopes has been further improved. This improvement has elevated typical magnifications from several thousand times to several tens of thousands of times, even reaching the level of traditional entry-level field emission microscopes.

Correspondingly, ion sputtering instruments have also upgraded from diode sputtering to mainly magnetron sputtering. Typically, for magnifications less than 20K times, gold (Au) deposition is mainly used. In the range of 20K to 100K times, platinum (Pt) deposition is primarily utilized, addressing most filament SEM scenarios.

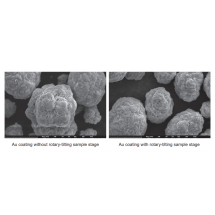

To meet the demands of an increasing number of 3D sample scenarios (such as powders, particles, porous materials, fibers, etc.), we have independently designed a digital rotary-tilting sample stage. This innovation ensures more uniform film deposition and enables three-dimensional angular rotation deposition, effectively solving the issue of side coating for samples. This feature is particularly advantageous for 3D powder and porous sample SEM preparation.

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM