Achieve excellent throughput, reliability, and low cost of ownership with the YES-PB Series tabletop vacuum cure. Patented YES technologies for vacuum curing ensure shorter cure time and increase throughput over atmospheric curing by more than 2-3x, with better outgassing, and better thermal and dielectric properties. The PB Series system is used extensively for polyimide, epoxy and wafer-to-wafer (WtW) bonding anneal. Using YES’s lab-to-fab capabilities, develop and test your innovative product ideas on the PB Series and when ready to scale, transition seamlessly up to the high-volume production VertaCure system.

Innovative Technology

Precise process control, with excellent temperature uniformity and laminar gas flow

The YES-PB Series features innovative technology to improve vacuum curing speed, reliability, and efficiency while extending equipment life.

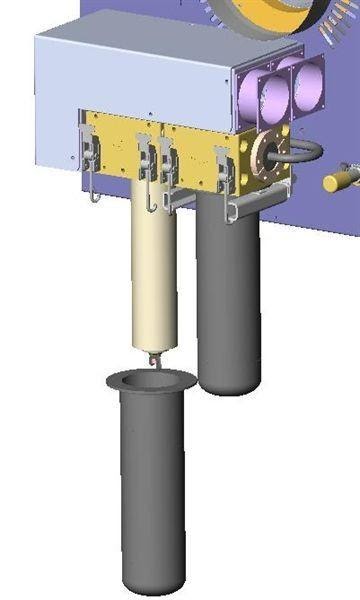

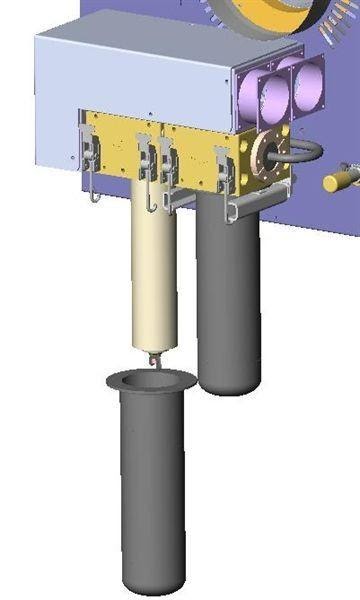

Chamber Exhaust Condensate Trap

Protect vacuum lines, valves, and vacuum pump performance from the accumulation of solvent condensates during the cure process. Easily dispose of the condensates.

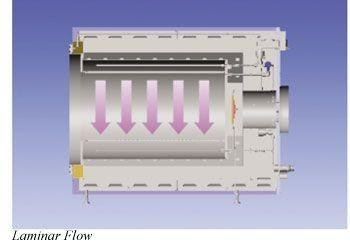

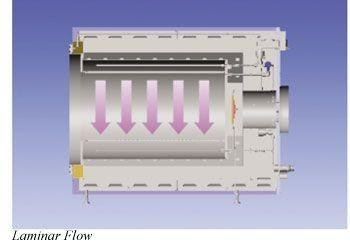

Vertical Laminar Flow Technology

The PB Series directs gases from top to bottom to eliminate gas turbulence, resulting in excellent temperature uniformity and particle performance.

Air Cooling Technology

Achieve optimal temperature uniformity and rapid cooling times with air. Adjust air mixing ratio for chamber cooling and precisely control ramp down rates.

FEATURES

- Vacuum processing with excellent pressure control

- Operating temperature: ambient to 450°C (optional high temperature version: ambient to 550°C)

- Temperature uniformity: ± 5°C during dwell

- Laminar gas flow parallel to the wafers

- Pump and purge cycles to reduce O? content

- Optional process management software: SEMI E5-0308 and SEMI E30-0307 compatible module

BENEFITS

- Faster process: 3.5 hours vs 8+ hours

- Laminar flow reduces/eliminates particles

- Less than 10ppm O? concentration after 3 pump and purge cycles

- More complete cure (5x less outgassing)

- 1.6x to 2x less power and N? consumption

- Much lower capital cost, 2-3x lower CoO

APPLICATIONS

- Polyimide/PBO cure

- BCB bake

- Low temp polymer cure

- Copper anneal

- Low-K dielectric cure

SECTORS

- Advanced Packaging

- CMOS Image Sensor

- Fan-out Wafer Level Packaging (FOWLP)

- Semiconductor Front-end Anneal and Degas

- RF Devices

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM