Greatly improved mixing performance with the same features as existing models!

A new advanced function model equipped with the individual revolution and rotation speed control system!!

400ml × 2 cups

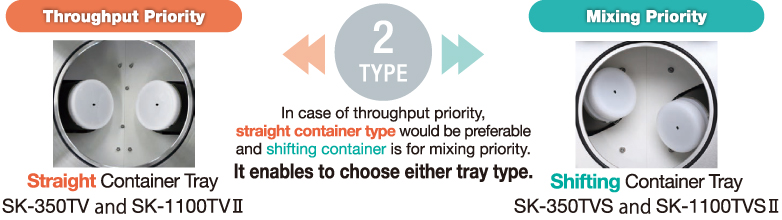

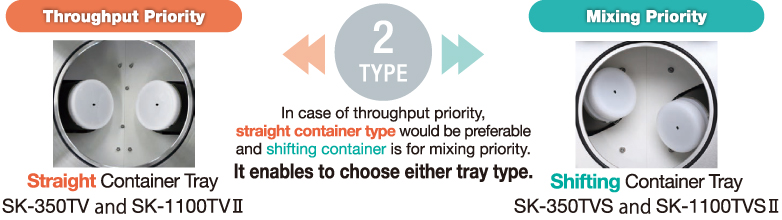

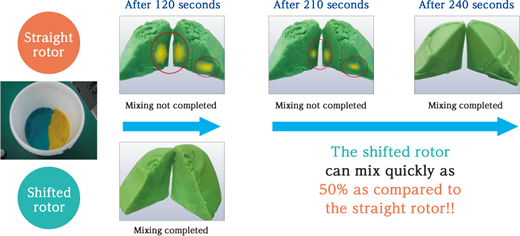

2 types of cup trays are available:straight (SK-350TV) and shifted (SK-350TVS), selectable according to the purpose.

While the straight type prioritizes throughput of materials, the shifted type offers improved mixing capability as compared to the straight type by increasing the contact part between the container inner wall and material.

* The effect differs depending on the material. Select the type according to the required throughput and mixing performance.

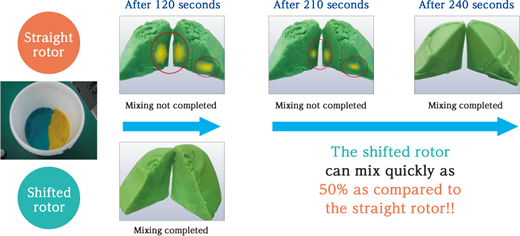

Comparison of mixing times (straight rotor vs. shifted rotor)

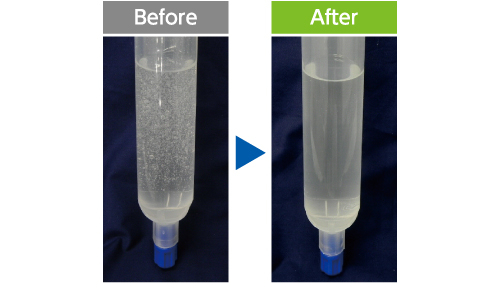

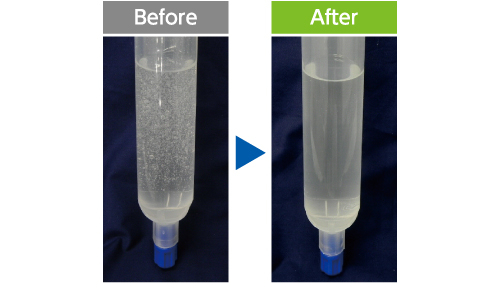

Equipped with a vacuum machine for enhanced degassing performance!

The vacuum machine makes it possible to eliminate even very finer air bubbles, so it can be expected to even further improve the conductivity and insulation performance demanded of electronic materials, reduce the rate of defective products due to bubbles in optical materials and prevent injection of air due to air bubbles in syringes.

Specifications

| Cup tray size |

400ml × 2 cups, Maximum 350g (Gross Weight) x 2cups |

| Other containers |

Multiple containers and syringes can be used by using an adapter. |

| Revolution setting |

Settable in 9 steps |

| Rotation setting |

Settable in 10 steps

(0 to 1.0 times with against revolution speed)

*May differ from actual specifications. |

| Time of setting |

10-300 sec. (in units of 10 sec.) |

| Step mode |

1-5 steps (Up to 5 types of different operation patterns (conditions) can be set continuously.) |

Memory channels

(condition setting memory) |

User settable channels 90

Fixed data channels 10 |

| Power supply voltage |

Single phase AC 200 ~ 240VAC

50/60 Hz |

| Power consumption |

2.0 kW (including vacuum pump) |

| External dimensions |

565 (W) × 682 (D) × 725 (H) (mm)

(not including projecting parts) |

| Main unit weight |

Approx. 160 kg (not including vacuum pump) |

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM