STELLAR® Freeze Dryer

Versatile Laboratory Freeze Dryer

Looking for a freeze drying workhorse for your lab? We have listened to all of your requests for a hardworking, versatile lyophilizer to be used in applications from proof of concept to small scale production. The STELLAR Laboratory Freeze Dryer provides more performance and capacity than any other unit in its class offering up to 6.25 sq. ft. (0.591 sq M) of shelf area and a condensing rate of 12 Liters in 24 hours.

Millrock Technology’s economical STELLAR Laboratory Freeze Dryer combines many of the features of larger systems, such as the Opti-Dry®and PLC lyophilization control system, into a small package. It’s ideal for most labs, fitting a wide array of freeze drying applications from investigational laboratory work to diagnostic kits. This tray lyophilizer combines top of the line components and design techniques in addition to options such as: a manifold, capacitance manometer, hydraulic stoppering, and more.

SYSTEM PERFORMANCE

- 5 Shelf pull down from +20 to –40C in less than 30 minutes

- Vacuum pull down to 100 mT in less than 20 minutes

- Vacuum leak rate less than 30 mT per hour

- Vacuum level 10 mT in clean dry system (-85C)

Specifications

CONTROL SYSTEM

- PC/PLC with ethernet and remote connectivity

- Cycle Assist Protocol Generator

- Manual and automatic operating modes

- Automatic system and leak rate testing

- Predictive maintenance

- User definable batch reporting - date, operator, recipe, data, graphic, and alarms graphic and numeric data collection

SHELF SYSTEM

- Up to 6.25 sq. ft. of shelf area

- 10″ x 18″ each shelf size

- Bulk or pneumatic stoppering option (Option: Increased stoppering pressure for 2ml vials)

- 316L stainless steel on all wetted parts

CONDENSER

- Internal condenser with baffle

- Exposed coil condensing surface to eliminate vapor bypass

- Hot gas defrost

REFRIGERATION

- Hermetic compressors

- CFC-Free, non-proprietary refrigerants

VACUUM

- Pirani vacuum sensor with solenoid control

- Gas backfill

- Corrosion resistant vacuum pump

- Option: Capacitance manometer with proportional control

FITTINGS

- Sanitary and KF fittings on all chamber access ports

Note: Specifications subject to change without notice. All specifications based on 20C ambient on 60Hz.

|

STELLAR STANDARD FEATURES

|

| SHELF AREA |

3.75 to 6.25 sq. ft. (0.348 to 0.581 sqM) |

| SHELF ASSEMBLY |

Bulk or Pneumatic Stoppering |

| SHELF TEMPERATURE RANGE |

-45ºC to +65°C (-53C Condenser)

-70ºC to +65°C (-53C Condenser) |

| SHELF HEAT TRANSFER |

Hollow Fluid Filled |

| SHELF SIZE/FINISH |

10″x18″, 316L SS, 20 Ra or better (254mm x 457mm) |

| CONDENSER TEMP |

-53°C or -85°C |

| CONDENSER CAPACITY |

12L |

| CONDENSER RATE |

12L in 24 hours |

| CONDENSER STYLE |

Internal Exposed Coil w / Baffle |

| DEFROST |

Hot Gas |

| COMPRESSORS (SCROLL) |

(-53C) 2 HP

(-85C) 2 HP 1st Stage and 2 HP 2nd Stage |

| PRODUCT SENSORS |

4, Type T Thermocouples |

| VACUUM PUMP |

Corrosion Resistant |

| VACUUM CONTROL |

Pirani w/ Solenoid & Needle Valve

Option: Capacitance manometer with proportional control |

| GAS BACKFILL |

Included |

| CONTROL SYSTEM |

PC/PLC with OptiDry Software |

| TRAYS |

One per shelf included |

| CABINET |

35″w x 42″d x 64″h |

| ELECTRICAL FOR -53C UNITS |

230V/60Hz, 1ph, 30A

220V/50Hz, 1ph, 30A

380V/50Hz, 3ph, 15A |

| ELECTRICAL FOR -85C UNITS |

230V/60Hz, 1ph, 30A

220V/50Hz, 1ph, 30A

380V/50Hz, 3ph, 20A |

Vial Capacity

VIAL

(ml) |

DIA

(mm) |

HT

(mm) |

# Shelves |

| |

|

|

1 |

2 |

3 |

4 |

5 |

| 2 |

16 |

41 |

480 |

960 |

1440 |

1920 |

2400 |

| 5 |

22 |

48 |

241 |

482 |

723 |

964 |

1205 |

| 10 |

24 |

58 |

199 |

398 |

597 |

796 |

- |

| 20 |

29 |

71 |

136 |

272 |

408 |

544 |

- |

| 50 |

43 |

81 |

55 |

110 |

165 |

- |

- |

* Capacity data shown in the above chart is an approximation.

Shelf Configuration

| SHELVES |

SPACING

(in/mm) |

Area

(sq ft/sq M) |

| 3 |

4.5 / 114 |

3.75 / 0.348 |

| 4 |

3.25 / 82 |

5.0 / 0.464 |

| 5 |

2.5 / 63 |

6.25 / 0.581 |

Bulk Fill

| Depth |

1 |

2 |

3 |

4 |

5 |

| 10mm |

1.0 |

2.3 |

3.5 |

4.6 |

5.8 |

| 15mm |

1.7 |

3.5 |

5.2 |

6.9 |

8.7 |

| 20mm |

2.3 |

4.7 |

7.0 |

9.2 |

11.6 |

* Capacity data shown in the above chart is an approximation.

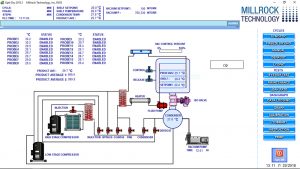

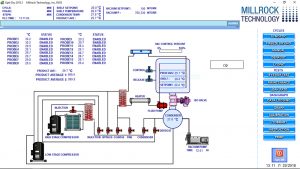

OPTI-DRY® PC/PLC Control

Laboratory Freeze Dryer comes complete with PLC controls and a PC for programming and data collection. Our easy-to-use software, Opti-Dry, provides automatic freeze-drying, defrost, and system test. Data can be printed either numerically or graphically. This same control system can be used on industrial dryers, allowing scaling to production. An interactive maintenance screen simplifies component servicing.

OPTI-DRY uses an ethernet platform for hardware connectivity making data transmission extremely fast. It also provides web connectivity for those who want remote access to their systems.

Available Options

MECHANICAL

- Clean room configuration

- Hydraulic Stoppering (2ml vials)

- Water Cooled Condenser

- Shelf latching kit to change shelf inter-distance

- Isolator interface for connection to an isolator

- Stainless steel door when using solvents

- LN2 trap to protect your vacuum pump from solvents

- H2O2 integration for sterilization

- 12 or 24 Port Manifold

INSTRUMENTATION AND CONTROLS

- Up to 16 thermocouples

- Resistivity probe

- 21 CFR Part 11 capable software

VACUUM

- Capacitance manometer to control the same as production systems

- Proportional vacuum control (+/-2mT control)

- Dry vacuum pump for use when processing solvents

SERVICES

- Startup and training

- Software Validation

- Electro-Mechanical Validation documentation

- IQOQ, FAT and SAT documentation and execution

Applications

- Pharmaceutical Freeze Drying

- BioTech Freeze Drying

- Diagnostic Freeze Drying

- Freeze Drying Nutraceuticals

- Microbiome Freeze Drying

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM