Bring sophisticated vapor deposition technology into the research lab or academic environment with the YES-TA Series of dual-function HMDS prime and image reversal ovens. Get stable process results while minimizing costly, toxic chemical usage.

Replace “wet” coating and curing ovens with the YES-TA dual-function vacuum oven for lower cost of operation, higher speed, and more reliable process results. Use fewer chemicals while gaining total control over the deposition process environment with advanced control systems for temperature, process times, and chamber size. The 58TA form factor fits well in any research or academic environment.

YES-TA vacuum coat/vapor prime systems provide fast, uniform, cost-effective priming of wafer surfaces with hexamethyldisilizane (HMDS) to improve the adhesion of photoresist. These versatile systems also support image reversal, forming negative images with the same resolution and ease as positive resist.

Effective photoresist adhesion forms the basis for all subsequent process steps, and only a totally primed surface will accurately reproduce submicron CDs without undercutting or ragged edges. The YES-TA Series vacuum coat dehydrates wafers thoroughly, enabling a superior bond with the HMDS layer that remains stable even after weeks of exposure to atmospheric moisture.

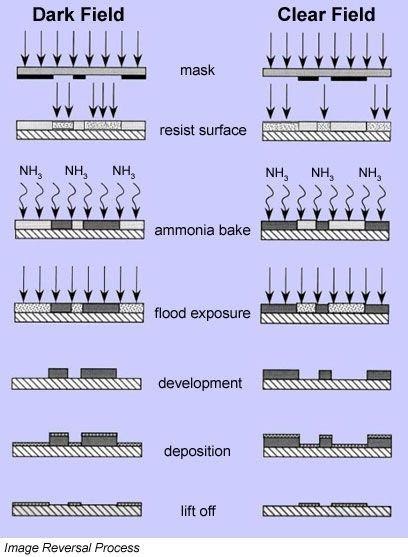

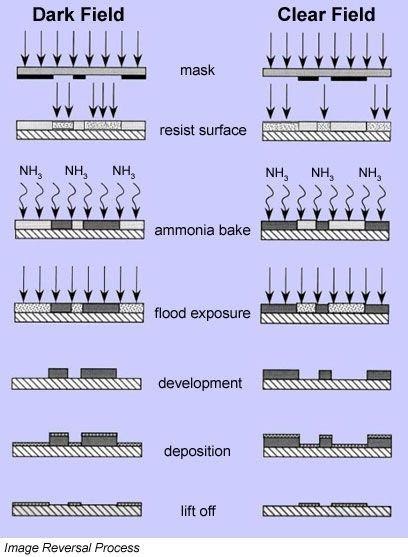

YES Image Reversal

YES solves the complexities of image reversal photoresist by delivering anhydrous ammonia (NH3) into the TA Series vacuum oven. This makes it easier to control vapor pressure as well as eliminate residual water vapor that can react with NH3 to form NH3OH, which is a corrosive to the system that can also create contaminating particles.

Features

- Control of liquid injection, vapor line temperature and exposure time

- N2 preheat to prevent chamber cooling

- Filtration mechanisms to reduce particulate introduction

- Surge suppression limits turbulence during chamber purge cycles to reduce particle count

- Advanced control systems for user-selectable temperature, process time and chamber size

- Vacuum cycles purge O? and water prior to HMDS for superior coating stability

- Eco-friendly “green” process

Benefits

- Fast, uniform, cost-effective priming of wafer surfaces with hexamethyldisilizane (HMDS) to improve photoresist adhesion

- Vacuum coat dehydrates wafers thoroughly for a superior bond

- HMDS layer remains stable even after weeks of exposure to atmospheric moisture

- Advanced control systems offer user-selectable temperature, process time and chamber size

- Lower chemical consumption and chemical cost

Applications

- MEMS

- CVD films are typically self-assembled monolayers (SAMs); used as anti-stiction coatings

- Lithography

- HMDS prime for photoresist adhesion

- As an adhesion layer between the polymer and the substrate

- As very thin and conformal release layers between the stamp and polymer materials

- Inkjet

- To prevent ink accumulation on the nozzle face plate to ensure unrestricted ink flow

- Bio-MEMS

- Hydrophilic and biocompatible CVD films can be used to improve wetting, or to prevent protein absorption, or to reduce “drift” in device performance

- Silane/substrate adhesion for microarrays: DNA, gene, protein, antibody, tissue

- Optical and AR/VR applications

- To modify optical properties

- To create nano-imprint layers or passivation layers

- Image Reversal

- Metal lift-off processing for etch-free process in WLP, RDL and mask-making operations

SingaporeSG

SingaporeSG ChinaCN

ChinaCN MalaysiaMY

MalaysiaMY IndonesiaID

IndonesiaID MyanmarMM

MyanmarMM